Do Phuoc Tong, chair of Duy Khanh Engineering, said an European company contacted Duy Khanh and placed orders with the enterprise when its Chinese supplies were interrupted because of Covid-19.

The company wants 10 products of different kinds and Duy Khanh has sent sample products to the company for consideration.

Soi The Ky, a synthetic fiber producer, which has factories in HCM City and Tay Ninh, reported that the company’s revenue in the first two months of the year increased by 15 percent compared with the same period last year, partially thanks to the increase in number of orders from the partners who could not receive supplies from China because of Covid-19.

Soi The Ky’s factories are running at full capacity. Nguyen Phuong Chi, strategic director of the company, said many more orders have come from the manufacturers in South Korea, Thailand, Japan, Taiwan and the US.

Meanwhile, foreign invested enterprises (FIEs) which are Soi The Ky’s partners, have increased orders.

| International manufacturers are seeking component suppliers in Vietnam, considering Vietnam as an alternative market in the context of Covid-19 escalation. |

Le Nguyen Duy Oanh, deputy director of the HCM City Supporting Industry Development Center, confirmed that because of the supply disruption from China, FIEs in Vietnam and manufacturers from other countries contacted the center and asked to help find suppliers.

At least five well known manufacturers, including two from Japan and South Korea which have production bases in China, and one from Germany, have asked for help. The enterprises specialize in manufacturing household use electronics and industrial machines. They need precision mechanical products and electronic components.

According to Oanh, the demand from the enterprises is high as they make products for export to many markets in the world. They provide opportunities to Vietnamese enterprises in supporting industries.

Analysts say that Covid-19 has made manufacturers realize that they should not continue to take risks by relying too much on supplies from China.

“This will benefit Vietnamese suppliers,” Chi commented.

However, the analysts warned that it will not be easy to grab the opportunity.

A representative of Duy Khanh Company admitted that the company’s products have high quality, but are uncompetitive in price compared with Chinese products.

Meanwhile, Oanh said most Vietnam’s enterprises are small scale which have low capacity of organizing mass production, so the production cost is high. In many cases, they cannot supply products ordered by partners because of the lack of machines and technology, and low qualifications of workers.

Thanh Mai

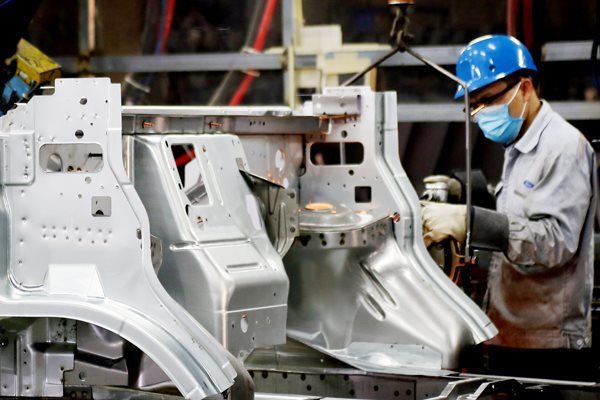

Supporting industries leading automakers towards success

Vietnam is striving to successfully build up its automobile industry.

Supporting industries secure more orders following Chinese supply disruptions

A number of local firms in supporting industries have been receiving more orders from foreign partners due to the coronavirus outbreak disrupting supply chains in China.

International manufacturers are seeking component suppliers in Vietnam, considering Vietnam as an alternative market in the context of Covid-19 escalation.

International manufacturers are seeking component suppliers in Vietnam, considering Vietnam as an alternative market in the context of Covid-19 escalation.